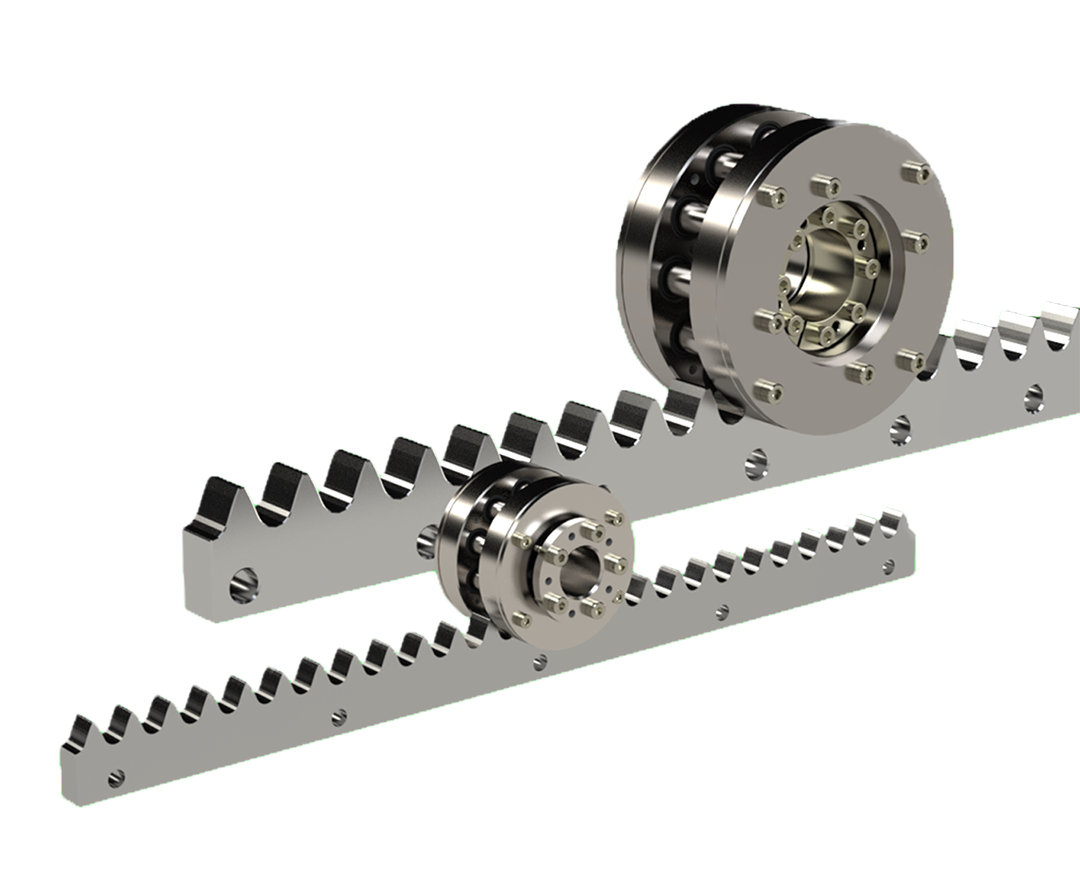

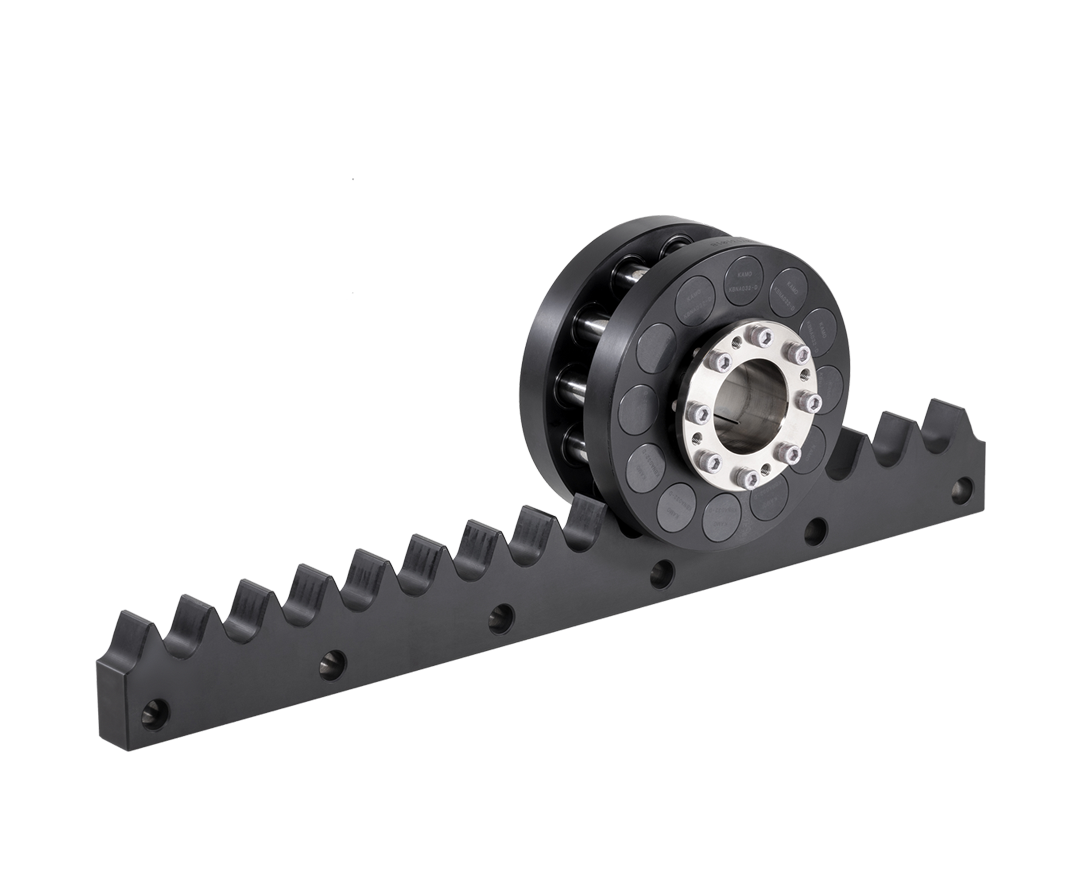

TCG Runner Stainless-steel type, CRS&CPS series

This Cam Rack & Roller Pinion is made of stainless steel exactly taking over the features of Zero-backlash, high accuracy, low friction, low dusting, etc. of TCG Series.

This product has excellent corrosion resistance and anti-rust effect.

TCG Runner Model Calculator Technical InformationHighlights

-

Zero-Backlash

The teeth always mesh via two or three portions and eliminate backlash when rotated in one or another direction.

-

Extended length line and high speed driving

Extendable with use of the connection jig “CJ”. And, capable of high speed driving of 180 m/min or more.

-

High Accuracy

The combination of cam gear and roller pinion makes a positioning accuracy and feeding accuracy (rotation-linearity ratio) as nearly as the ball-screw.

-

Low noise・Low vibration

Rollers of Pinion supported by bearings roll smoothly on the trochoid gear. Thereby tooth striking noise, rotating noise and also vibration are reduced.

-

Low dust

Due to the smooth rotation, the structure dispenses with a least amount of heat and dust generated and cope with a clean room operation.

Model

Roller Pinion

*For the hold-down plate lock bolt, because the tap drill hole is a through hole, there is no specification for bolts with gas-vent hole.

- CPS

- 1

- 1610

- 2

- A

- A

- 4

- A

- 5

- 1.Product Name

- CPS series

- 2.Frame number

-

1610,2010,2510

- 3.Sealed grease

-

A:Standard

G:Supplied grease

*Sealed grease: If G (supplied grease) is selected, please note that the specification values may not be satisfied depending on the properties of the grease.

- 4.Precision cleaning

-

A:No

S:Yes

*Precision cleaning: If S (Yes) is selected: Vacuum packing is done after rust-preventive treatment is provided.

- 5.Lock bolt

-

A:Standard

B:With gas-vent holes

- CPS

- 1

- 3212

- 2

- A

- A

- 4

- A

- 5

- 1.Product Name

- CPS series

- 2.Frame number

-

3212,4012

- 3.Sealed grease

-

A:Standard

G:Supplied grease

*Sealed grease: If G (supplied grease) is selected, please note that the specification values may not be satisfied depending on the properties of the grease.

- 4.Precision cleaning

-

A:No

S:Yes

*Precision cleaning: If S (Yes) is selected: Vacuum packing is done after rust-preventive treatment is provided.

- 5.Lock bolt

-

A:Standard

*Lock bolts are provided only to the standard specifications because gas is released due to the structure of the clamping tool.

Cam Rack

- CRS

- 1

- 1610

- 2

- A

- 1.Product Name

- CRS series

- 2.Frame number

-

1610,2010,2510,3212,4012

- 3.Mounting hole

-

F:Side mount hole only (standard)

Y:+ Tap at bottom surface

- 4.Length of Cam Rack

- For the length of the cam rack,(“Cutting Dimensions of Cam Rack” on P.21.) *Other than the cutting dimensions table are also available. Please contact.

- 5.Precision cleaning

-

1:No (standard)

2:Yes + Standard grease is applied in the packing process. Alvania Grease S2 (Shell Lubricants Japan) is applied.

3:Yes + Supplied grease is applied in the packing process.

*For the reason that the cam rack is made of martensitic stainless steel, the following rust-preventive treatment is provided to all over the surfaces in the packing process.

*Precision cleaning: If Yes is selected: Vacuum packing is done after rust-preventive treatment is provided.

Cam Rack Connection Jig

*The connection jig is shared with CRA and CRC Series.

- CJ

- 1

- 16

- 2

- B

- 1.Product Name

- CJ series

- 2.Frame number

- 16,20,25,32,40

Materials

The materials of the parts used for the products are as follows.

Cam Rack

Martensitic stainless steel

Roller pinion

| Pinion body | Austenitic stainless steel |

| Hold-down plate | |

| Bolt | |

| Clamping tool | |

| Roller | Martensitic stainless steel |

| Oil seal | Nitrile rubber (NBR) |

Connection jig

Carbon steel for structural use

Specifications

ModeItems |

||

|---|---|---|

| Roller Pinion | ||

| Cam Rack | ||

| CPS/CRS series | ||||

|---|---|---|---|---|

| CPS1610A | CPS2010A | CPS2510A | CPS3212A | CPS4012A |

| CRS1610A | CRS2010A | CRS2510A | CRS3212A | CRS4012A |

| Common spec. | Basic dynamic rated load | N |

|---|---|---|

| Maximum working load | N | |

| Allowable static rated load | N | |

| Basic dynamic rated torque *1 | N・m | |

| Maximum working torque *1 | N・m | |

| Allowable static rated torque *1 | N・m | |

| Displacement distance of pinion per rotation | mm/revolution | |

| Max pressure angle | ° | |

| Module | mm | |

| Roller Pinion | Number of tooth | teeth |

| Diameter of pitch circle *2 | mm | |

| Mass weight | kg | |

| Inertia moment | ×10-4 kg・m2 | |

| Cam Rack | Pitch | mm |

| Predetermined length | mm | |

| Number of tooth | teeth | |

| Mass weight | kg | |

| Outline Drawing | Roller pinion / Cam Rack | |

| Connection Jig | ||

| CAD Data | ||

| Catalog | ||

| Instruction Manual | ||

| 1000 | 1500 | 2200 | 3600 | 6000 |

| 1700 | 2200 | 3100 | 6600 | 9000 |

| 2000 | 3000 | 4400 | 7200 | 10940 |

| 25.5 | 47.7 | 87.5 | 220.0 | 458.4 |

| 43.3 | 70.1 | 123.4 | 403.3 | 687.6 |

| 59.9 | 95.5 | 175.1 | 440.0 | 836.0 |

| 160 | 200 | 250 | 384 | 480 |

| 30.7 | 30.1 | 30.7 | 30.1 | 30.0 |

| 4.75 | 6 | 7.5 | 9.5 | 12 |

| 10 | 10 | 10 | 12 | 12 |

| 50.9 | 63.7 | 79.6 | 122.2 | 152.8 |

| 0.81 | 1.5 | 2.4 | 6.8 | 16 |

| 4.56 | 12.5 | 29.6 | 200 | 728 |

| 16 | 20 | 25 | 32 | 40 |

| 992 | 1000 | 1000 | 992 | 1000 |

| 62 | 50 | 40 | 31 | 25 |

| 2.2 | 4.1 | 5.4 | 8.3 |

13 |

*1 Basic dynamic rated torque (maximum working torque, allowable static rated torque) is torque observed when applying basic dynamic rated load (maximum working load, allowable static rated load) to roller pinion along diameter formed by pitch circle

*2 The indicated pitch circle diameter values are theoretical, not representing the actual pitch circle diameters of the respective roller pinions

TCG (Trochoid Cam Gear) Line-up

-

TCG Runner,

CRA&CPA / CRC&CPC series

- Frame number

-

CRA&CPA:1010,210,1610,2010,2510,3212

CRC&CPC:3212,4012

- Maximum working load(N)

-

CRA&CPA:250 - 6600

CRC&CPC:10500 - 18000

-

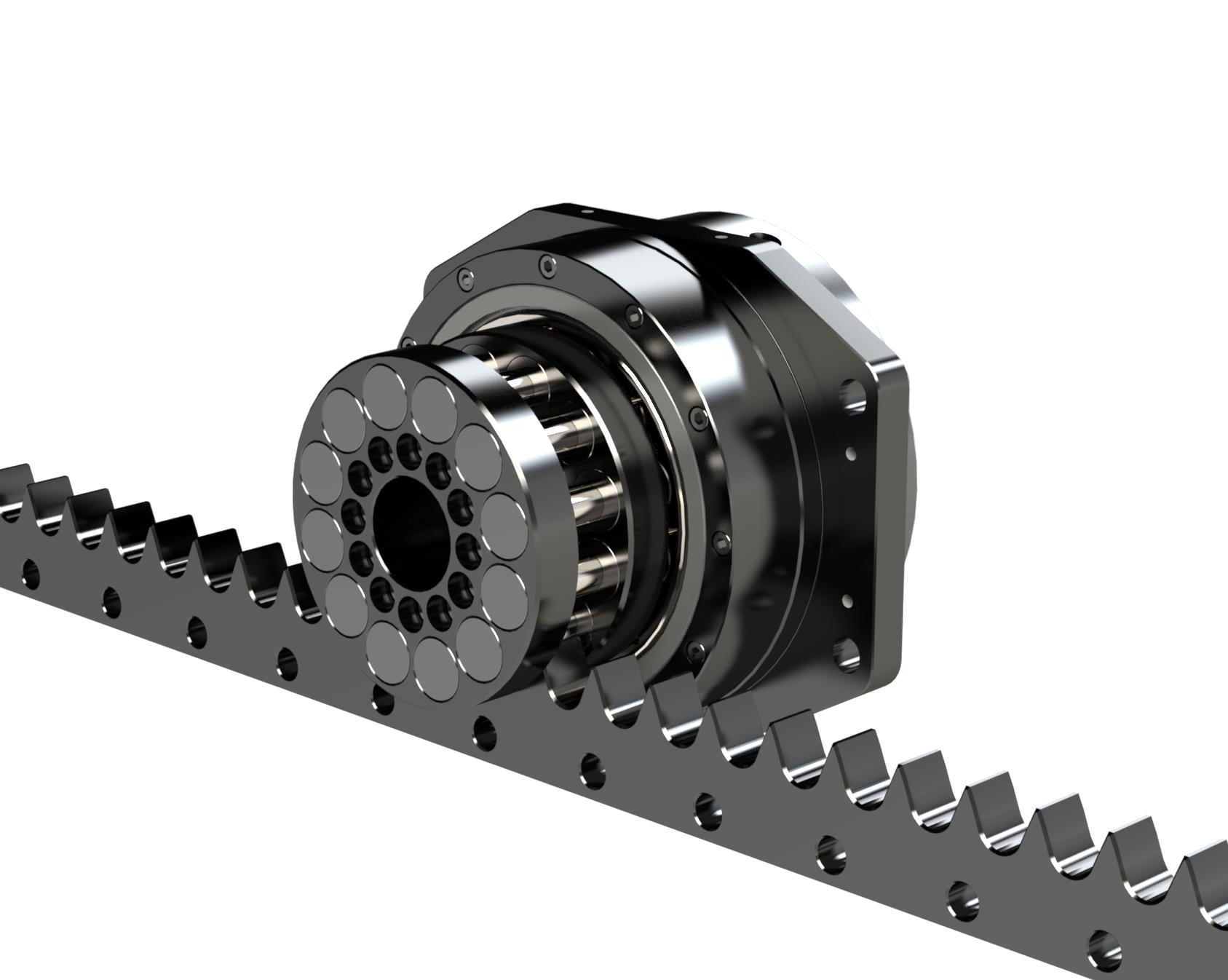

Precision Ball Reducers

for TCG Series 1210-2510, SFP Series

- Frame number

- 70,85,100,125

- Reduction ratio

- 8 - 50

- Acceleration peak torque(N・m)

- 9.5 - 123.4

-

Precision Differential Reducers

for TCG Series 3212-4012, NSP Series

- Frame number

- 70,85,100,125

- Reduction ratio

- 8-50

- Acceleration peak torque(N・m)

- 9.5-123.4

-

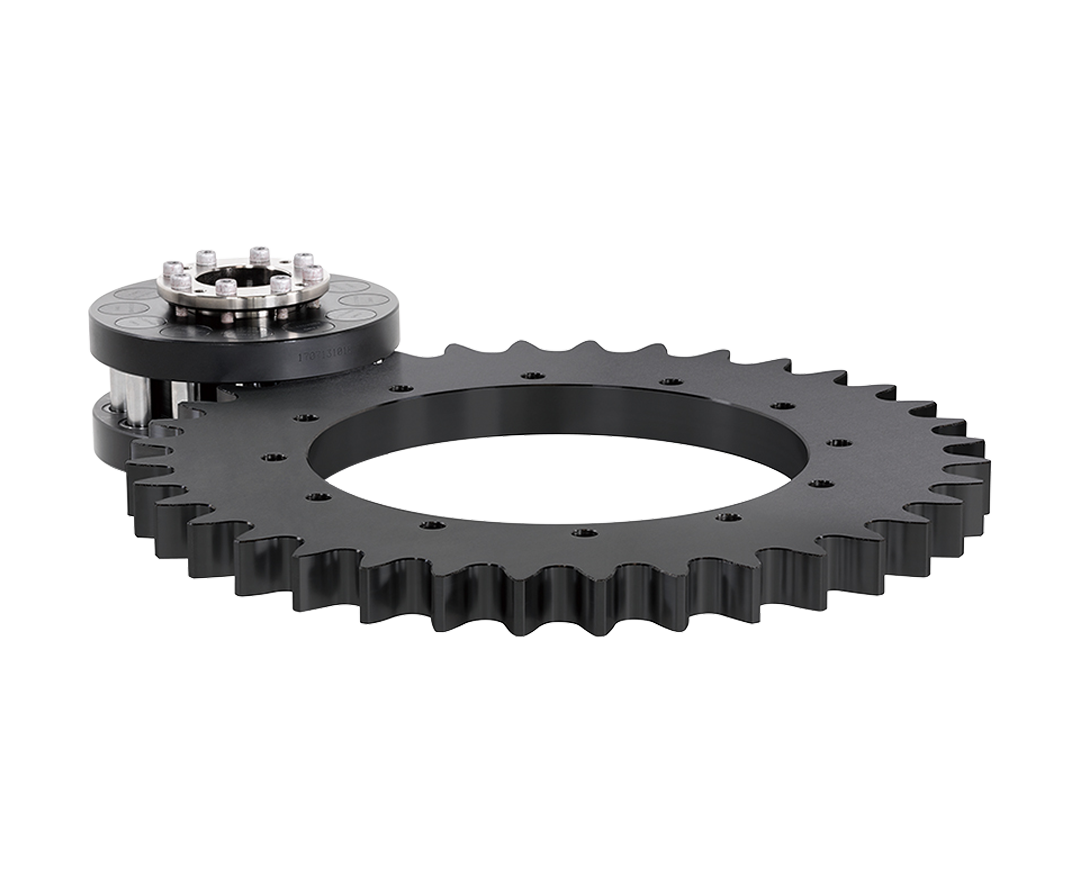

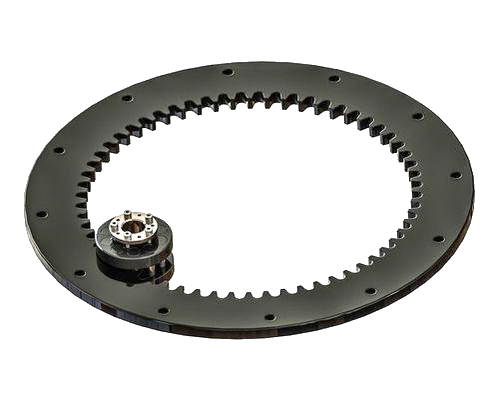

TCG Ring(Full Ring),

RGF&CPA / RFC&CPC series

- Frame number

-

RGF&CPA:1010,1210,1610,2510,3212

RFC&CPC:3212,4012

- Maximum working torque(N・m)

-

RGF&CPA:11 - 1930

RFC&CPC:1800 - 5300

-

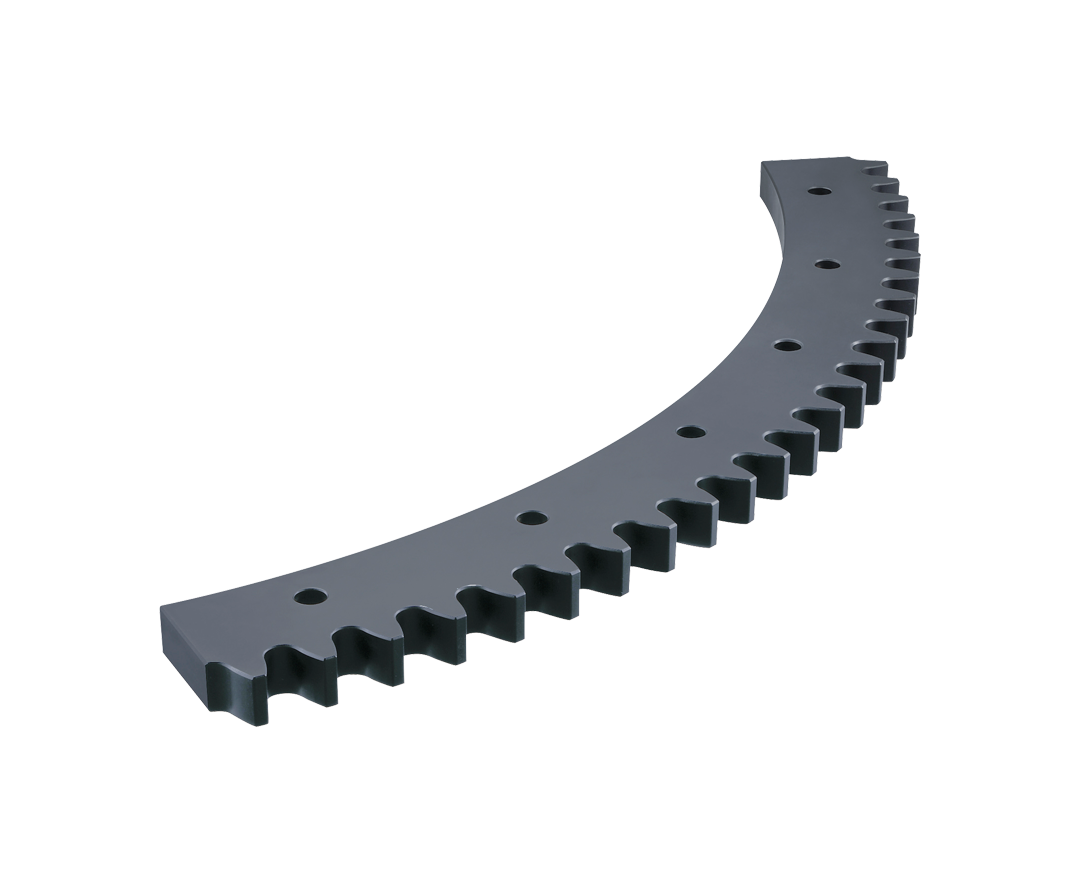

TCG Ring(Circular Arc Ring),

RGD&CPA / RDC&CPC series

- Frame number

-

RGD&CPA:1610,2510,3212

RDC&CPC:3212,4012

- Maximum working torque(N・m)

-

RGD&CPA:585 - 6430

RDC&CPC:3800 - 17500

-

TCG Ring Internal-gear type

(Full Ring),UGF&CPA/UFC&CPC Series

- Frame number

-

UGF&CPA:1610,2510,3212

UFC&CPC:3212,4012

- Maximum working torque(N・m)

-

UGF&CPA:245-1550

UFC&CPC:2460-3990

-

TCG Ring Internal-gear type

(Circular Arc Ring),UGD&CPA/UDC&CPC series

- Frame number

-

UGD&CPA:1610,2510,3212

UDC&CPC:3212,4012

- Maximum working torque(N・m)

-

UGD&CPA:535-9600

UDC&CPC:6910-32000

-

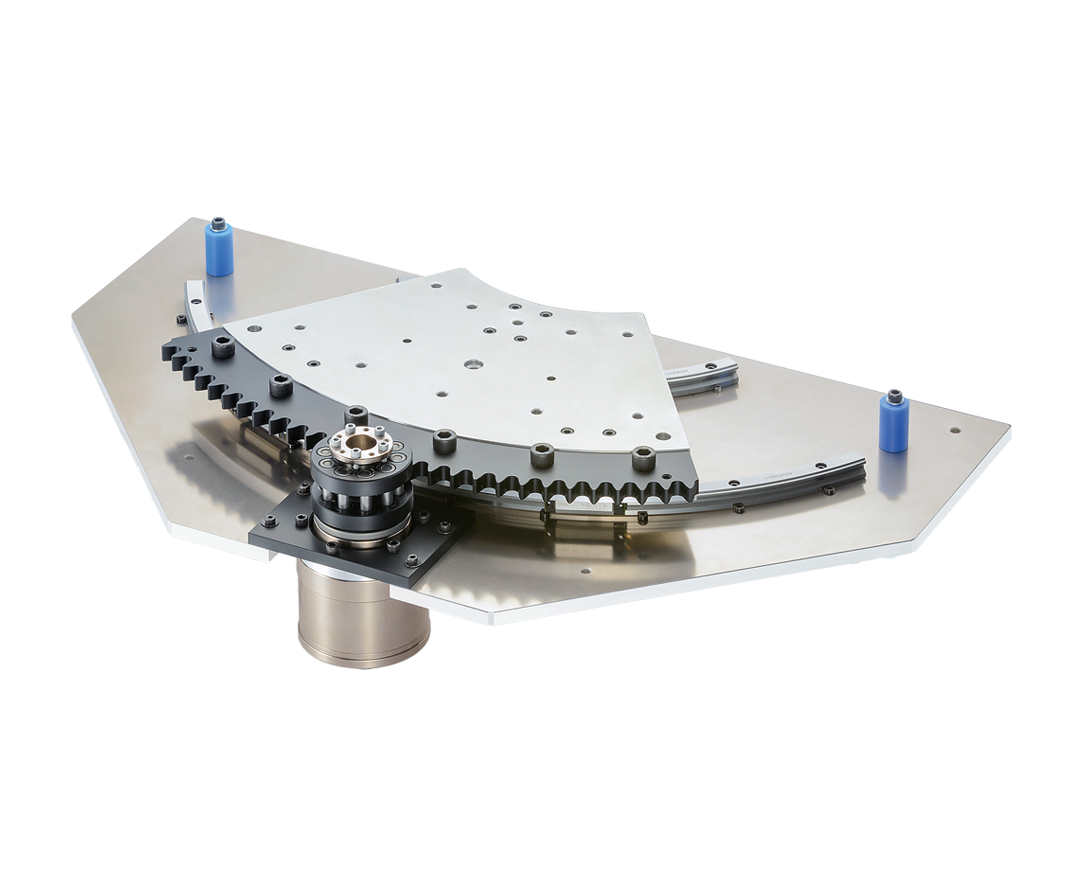

Full Ring Unit

RGU series

- Frame number

- 1610,2510

- Reduction ratio

- 40 - 625

- Maximum working torque(N・m)

- 143 - 1496

-

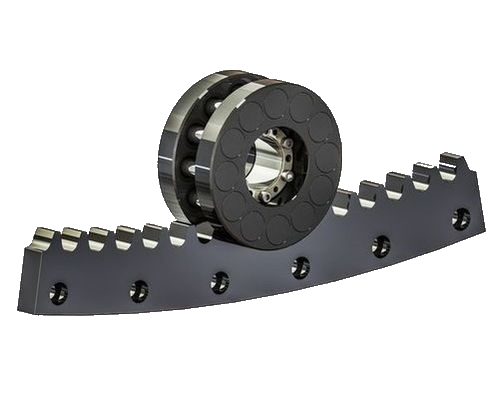

Circular Arc Ring Unit

RGU series

- Frame number

- 1610,2510

- Reduction ratio

- 150 - 1200

- Maximum working torque(N・m)

- 945 - 2270